Process Control, the Heart of Refinery

Process control ranges from a manual valve controlled by an operator to a fully automated control unit.

Process control is at the heart of refinery and it's inevitable that we dedicate 70% of our time making sure that we do not have a run-away process or reactor which will cost our clients millions of money, time, and environmental pollution.

Environmental Impact Assessment (EIA)

We all have a role to play in protecting the environment. That is why we are committed to environmental impact assessment (EIA) throughout our activities and keep improving the way we carry out installations and various activities.

Oil and Gas Processes

Oil and gas have become the most widely used source of energy. Processes have been developed to convert the naturally deposited Oil and gas called crude oil into useful, everyday energy sources. Crude oil refineries have been built all around the world to convert crude oil into energy sources.

A modular or sectional refinery is a streamlined or basic refinery necessitating less financial cost and less asset capital investment than the full-scale refinery facilities. They are built to suit crude oil input feeds and customers' required output or product.

How we build your Modular Refinery

There is a lot that goes into building a refinery. We have put together a major milestone that can help our client visualize the steps and this is not an exhaustive list.

For more information, please contact our chemical and Refinery engineers.

1. Crude Oil Assay/ Analysis

______________

This is the stage where we ratify the crude oil assay. In most cases, the assay is readily available. We have over 24 countries' crude oil assays that we work with.

2. Clients' required Output specified and appropriate Modules Selected.

_______________

It is important to know what the refinery's output is going to be before venturing. Thus, customers need to be well informed of various outputs

3. Storage Capacity

_______________

This is the first stage of the analysis. The required storage capacity needs to be clarified for continuous production.

4. Simulate the Modular Refinery

____________

The refinery simulation gives the engineers the idea of how the refinery is going to behave and the required analysis conducted. This includes the Steam distribution required, material balance etc.

5. Finalize the Refinery

________________

This is the biggest step in the building of the refinery. This is where all engineers come together to work on the project. Mechanical, Electrical, Civil engineers, etc to work on the project

6. Start assembling your refinery

________________

This is where the actual assembling of the modules start with the trial run of the refinery

7. The Final Product to our client

Pretreatment Processes

01 Storage Tanks

02 Desalter Process

White Big Storage Tanks for Crude Oil Blends

These are huge tanks that hold all the incoming crude oil of the industry. It is also often used in mixing several grades of crude oil. The picture shown here is the refinery storage tank farm used for storing crude oil before they are further processed through other plants.

Storage tanks are quite important in any refinery since they are the ones that hold the amount of crude required for other plants to operate on. From the pictures, the dug rectangular area part surrounding the tanks is called the bund walls. This is a good practice to avert spillage when there is an overflow from the storage tank which can cause a domino effect. The construction of the bund wall depends on adequate scaling to the volume of the tank. The dimensional analysis is as shown here:

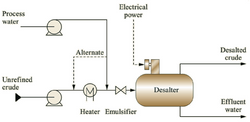

Crude oil often contains water, inorganic salts, suspended solids, and water-soluble trace metals. As a first step in the refining process, to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning the catalysts in processing units, these contaminants must be removed by desalting (dehydration and salting-out process).

Desalting and dewatering of crude oil upstream of the crude distillation unit is a key process operation for the removal of these unwanted components from crude oil before they get to other major unit operations. The operation of a desalting system can be very challenging due to changing process variables due to varying crude oil composition- mixture different of hydrocarbons and other impurities (sulfur (S2-), nitrogen (N3-), oxygen (O2-), and metallic ions-Ca2+, Mg2+etc). At best, it is a process of measuring trade-offs and compromises.

|  |  |

|---|---|---|

|  |

03

Simplified Animation of primary modules of Crude Oil refinery

Pipeline/shippment/transportation of crude oil

Storage Tanks for continuous supply of Crude Oil

Desalter Process to remove Salts and other impurities using Steam Distribution system

Heater/Burners to heat up the Crude oil

Atmospheric Distillation Column

Vacuum Distillation Column for Light to Heavy Oil

Residue from Distillation Column to Bituminous Plant

Different Fractions

e.g Kerosine, Petrol etc

Book Your Training

Some Important modules in Oil Refinery

The essential Gas scrubber. Scrubber systems are process plants for controlling the amount of pollutants emitted into the air from gases from the refinery or gases directly from crude oil upstream. The gas scrubber removes some particulates and/or gases from industrial exhaust streams.

This distillation tower is used to separate crude oil fractions after the crude oil have been desalted and heated to about 340 - 500 degree C.

.jpg)